Crown Packaging

Please tell us about your company and its history.

When was the company founded?

The company was founded in 2011 and the business started in January 2012.

Who founded the company?

The company was founded by the young entrepreneurial couple Gerard and Baukje van der Wal, together with a group of socially-minded investors from the Netherlands.

Can you please describe the history of the company?

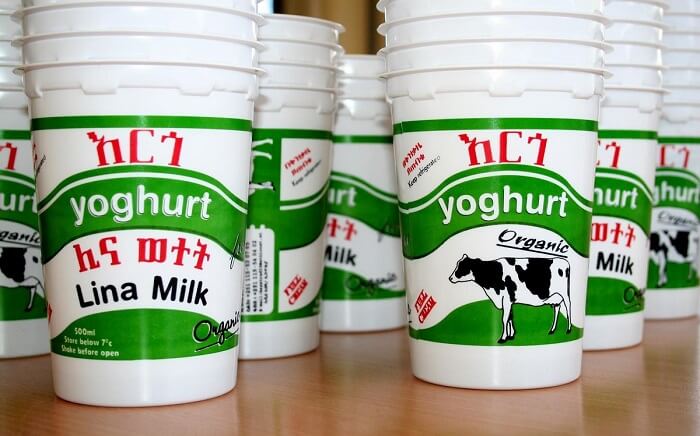

In 2009 the founders visited Ethiopia for the first time. There they saw the need for jobs and import substitution of materials. Then they met the owners of a dairy company who were buying their yogurt cups from abroad. At the time, all thermoformed packaging was being imported in the country. The founders then felt called to combine these things and start a new manufacturing plant.

In which sector is the company engaged?

The company manufactures thermoformed packaging for the food industry and events.

What is the objective of the company?

The company wants to serve its employees and customers by working according to high standards at competitive conditions. At the same time, the country as a whole must be better off due to the work of the company; the investors believe that this will, in the end, also result in a healthy financial return on their investment.

What is the production capacity of the business?

The company can produce approximately 350.000 cups per day. This is about double the current consumption in the country.

How many people does the company employ?

Crown Packaging currently employs a team of 69 people.

Any milestones (e.g. major partnerships agreements, expansion investments, shipment/production targets, etc.)

After starting production in a rented building in Dukem town, Oromiya, the company started construction of its own factory in 2015. The new buildings were constructed on a plot of land leased from the government in Udee Denkaka, just South of Bishoftu, Oromiya. The new location is strategically located at the expressway entrance road.

Can you tell us a little bit about yourselves (e.g. name and position in the company, role and responsibilities, why you personally are passionate about, why you established/joined the company, etc.)?

My name is Gerard van der Wal. From the start of the company in 20112 till 2018 I have served as general manager. My passion is to use entrepreneurship to have impact on people’s lives. Everything that we are entrusted with in life gives us a responsibility to use it for good. This is how we came to start this company. After my family and I returned to the Netherlands in 2019 I stayed closely involved. Thanks to the fact that our management team are running the company so well, I’m now able to look into new investment opportunities in Ethiopia with the same goals.

How did you become interested in investing in Ethiopia?

During our first visit to the country in 2009, we had seen that many people were eager to work but couldn’t find a job. At the same time, we saw opportunities to replace imported products with local production. Combining these things, we came up with the plan for Crown Packaging and Plastics.

What are the advantages of doing business in Ethiopia?

Compared to other African countries we have visited, we find the Ethiopian people eager to work. Also, the values and morale are good here. Altogether we have mostly enjoyed working with Ethiopian people and we see many more opportunities.

How is Ethiopia’s industrial market different from that in other parts of the world?

There are still a lot of things to develop. On the one hand, this makes me enthusiastic as an entrepreneur. On the other hand, it sometimes creates challenges – for example, when it comes to local availability of spare parts and such.

On that note, what are some trends you are seeing in the Ethiopian industries/market?

To be honest, we see quite a few people simply copying what others are doing. They are simply trying to get a piece of the success which they see at other places. We have sometimes seen new customer X coming to our company and just saying he wants to do what company Y is successful at. Personally, I understand that it feels safe to do business like that. At the same time, it will usually not lead to genuine success, both for the new company or for the country. It just creates more of the same without improvement.

Were there any challenges your firm faced while doing business in Ethiopia?

In general, we have been blessed and things have been going well. Of course, in each business you find challenges. For us the most important currently lies in the availability of forex for our raw material procurement. Our Dutch mother company has had to help us out a couple of times in that perspective.

Were there any specific strategies that your company established to better adapt to the Ethiopian market?

From the beginning, we have tried to listen to and learn from our team as much as we could. Our local team has from the beginning been one of the main reasons for the fact that our company is being successful. Also, being in contact with other investors has often helped us a lot.

What is your company currently doing to rise above the competition in the Ethiopian market?

We focus on being reliable as a supplier. Because our customers produce perishable products, it’s really important for them to be able to rely on us. In a few cases we have really had to pull a stunt to keep our promise to customers, but in almost all cases we have been able to. In general, we also keep watching what we can do to make sure our customers and team members are doing well. If that is the case, then we don’t feel a need to look too much at what competitors are doing.

What Ethiopian companies/government agencies do you work with to strengthen your business partnerships?

With EIC, the Ministry of Industry and Trade, and the Ethiopian Meat and Dairy Industry Development Institute (EMDIDI).

What advice would you give foreign investors/companies seeking to enter the Ethiopian market?

Build for the long run; don’t focus on short-term profits and benefits. Don’t look only after your own interests, but also after the benefit of those you work with and for.

How can Ethiopia become a more ideal business environment for foreign companies like yours?

Compared to the Netherlands where we come from, the government is sometimes involved quite a bit in the way business is done, or has to be done. For example, it’s not allowed here to be involved in a kind of business for which you don’t have a business license.

On the one hand, this sounds logical. On the other hand, some of the most successful companies in the world have become big doing something which they never planned for. Often it started as a try-out at the side of their core business. That little side business then grew out to become enormous. I believe that creating freedom for entrepreneurship and trial and error helps to achieve great things.

Of course, there has to be a good legal framework in which the work is being performed. But this doesn’t have to narrow down creativity.

How has the COVID-19 pandemic changed the way your company is conducting business here?

The hoax that consuming cold products would increase one’s chances of getting infected with the virus did reduce sales of yogurt somewhat. Also, there are now no events for which we usually produce cups. Then the temporary slowdown in exports in the country of course created tension with regard to the availability of forex and the value of the birr. But altogether we don’t want to complain. We have been able to keep our full team at work and our company is doing okay. There are others who have been much more seriously affected by it.

What are some future plans/goals that your company has in terms of doing business in Ethiopia?

Currently we are working to start manufacturing of processed and packed coffee products. At the moment, most value to coffee is added in the countries where it’s consumed; this is done mainly by machines and robots nowadays. We would rather do this with the people from the country where the coffee originates. This will not only create great coffee for the end user, but also jobs for people – who can then take care of their loved ones.

There are more ideas, but they need to cultivated further and might then come to existence one day. First, our focus will be on the existing business and the coffee manufacturing. Many of the best practices in our packaging factory will be used again for the new plant.